1987 - Inception

Jayanti Bhai Patel established Family Group Company as a Manufacturer and trader of Submersible Pump Spare Parts in Rented space of 300 Sqft with one lathe machine.

1990 - 1998 Invention

Invented Submersible Motor Thrust bearing through the process of Forging, Plastic Injection Moulding, Cast iron Casting plate, got excellent response from Customers. Established our own Foundry for Shell Moulded Castings.

2000 - 2001 Manufacturing

Family Group Company split into two Division one is Thrust Bearing and another is Shell Moulded Castings .Established "Dev Industries" as a manufacturer of Submersible Pump Parts through Shell Moulding Process.

2003 Impellers

With Lots of research and development, First to introduce Stainless steel Impellers instead of Gunmetal (Bronze) and we achieved good result in terms of Casting Inner surface finish in Shell Moulded Impellers.

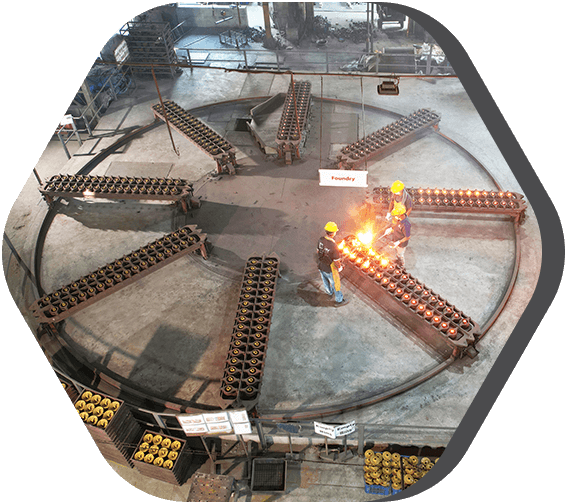

2005-2007 Infrastructure

Own Designed Semi Automatic Shell Moulding Foundry (Plant II) was Inaugurated. Metrology Lab with European Technology & Sand Lab was opened. Installed Japanese Machining technology at the heart of it. Adopted new technologies and enhanced output & acquired new customers. Established 3rd Shell Moulding Foundry for Ferrous Castings.

2010 Certification

Acquired the ISO 9001:2008 Certification from ISOQAR, also Achieved "Excellence in Innovation" Award.

2011-2014 : Technological Push

Established world class Machining facilities with Japanese Technology for sustain quality parameter in machining. In House Die Development started with Added facilities of Tool room equipped with CAD/CAM softwares and MAZAK make Vertical milling machines, new Software's like Simulations, Designing, Programming etc.

2015 : Exports

Started Exports to the Europe, America & rest of the world as well as Gulf countries.

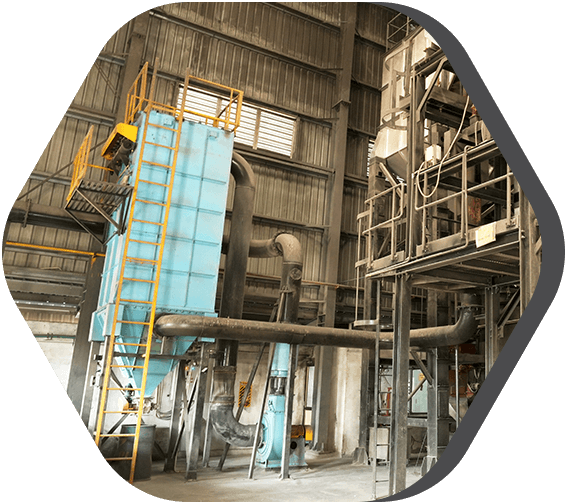

2016 : Save the Environment Project

Taken initiative for environment control and installed Sand Reclamation plant to reduce dumping of chemical sand.

2019 Expansions

State of the Art Shell Moulding foundry (plant III) established to accommodate new customers with Semi Automated Pouring bed to boost productivity & Energy conservation. Achieved "Pride of Gujarat" awarded by Chief Minister of Gujarat.

2020 - 2021 Pandemic Support

During COVID-19 Pandemic situation our whole Dev group Team supported to patients who were admitted to hospital by giving them Tiffin Seva. 500 nos Food Dishes were served on daily basis in our region.

2022-25 : Keeping pace with Industry 4.0

Upgraded all in house CNC, VMC, Balance etc machines with IOT implementations to avoid Introduced Auto offset correction system in all CNC machines with theme quality at the source.